- #Fishbowl inventory manufacturing software serial

- #Fishbowl inventory manufacturing software software

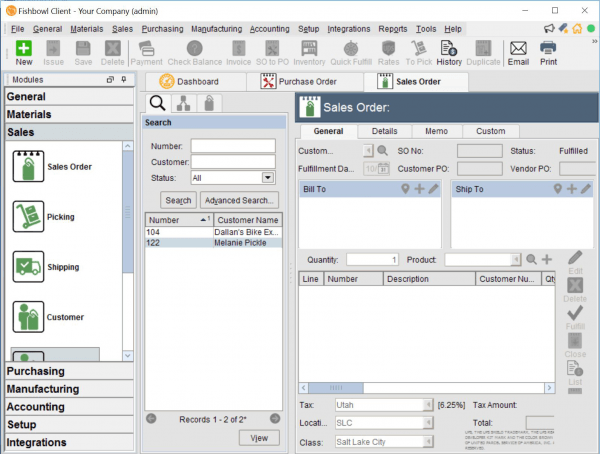

The service includes remote and on-site assistance, so the manufacturer can get it the way they want. It is easy to find a reliable provider that offers assistance for every budget and requirement. Fortunately, companies have the option to collaborate with an expert for the implementation of the Fishbowl App as a service. But its implementation can be a daunting task because there is a concern about business disruption during the process. There isn’t a better option than Fishbowl for manufacturing companies looking to ramp up their inventory control processes. Fishbowl implementation for manufacturing companies It streamlines the entire operations and takes the business on the growth route. Apart from inventory management, the app can also help with other processes like packing, shipping, and receiving goods.

#Fishbowl inventory manufacturing software serial

Further, managers can track and categorize items according to parameters such as serial number, lot number, and expiry date.Įvery time the quantity of an item goes below a specific level, the system issues a notification so that the manager can order for replenishment. It automates and speeds up everyday tasks, which otherwise take a lot of time and effort.

#Fishbowl inventory manufacturing software software

The Fishbowl software goes a long way in addressing the challenges of inventory management for manufacturing businesses. The benefits of embracing Fishbowl software Let us explain how implementing it can add value to a manufacturing company. Thankfully, you can rely on Fishbowl Inventory Management for organizing your inventory data efficiently and securely. In both circumstances, your business could suffer from a loss in productivity, revenue, and sales. Conversely, overstocking can block your capital uselessly. Understocking leads to delays and bottlenecks in the workflows and an increase in operational costs. Handling things manually can result in human errors and incorrect stock levels. Inventory control and management are perhaps the most critical processes for a typical manufacturing business.

0 kommentar(er)

0 kommentar(er)